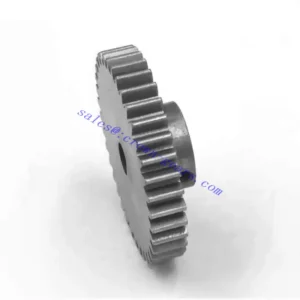

High precision heat treated Steel material crown wheel pinion bevel gear

As one of the crown gear manufacturers, suppliers, and exporters of mechanical products, We offer crown gear and many other products.

Please get in touch with us for details.

Mail:[email protected]

Crown Gear

Crown gears are an essential component in a wide range of mechanical systems, from industrial machinery to automotive applications. These gears are designed to mesh with other gears to transmit torque and power between shafts at right angles to each other. Crown gears are also known as bevel gears, and they are particularly useful in applications where space is limited, and the transfer of power or torque is required at an angle.

The design of crown gears is unique, with a special shape that allows them to mesh with other bevel gears. They are typically made from high-quality materials such as steel, brass, or aluminum, which ensures their durability and longevity. Crown gears are usually manufactured using advanced precision machining methods, which guarantees their accuracy and reliability.

One of the key advantages of crown gears is their ability to transfer power and torque smoothly between two shafts that are at right angles to each other. This makes them an ideal choice for applications where space is at a premium, such as in the automotive industry, where they are commonly used in differential systems. Crown gears can also be used in industrial machinery, such as mining equipment, where they are used to transfer power between vertical shafts.

Crown Gear Specifications

| Application | operating mechanism |

| Material | aluminum, steel, stainless steel |

| Surface treatment | black coating, phosphorization |

| Size | m=2.5 a=20° |

| Processing | CNC Machining |

Crown Gear Benefits

Smoother operation: Crown gears have a smoother operating profile than other types of gears, which reduces vibration and noise. This makes them ideal for applications where noise and vibration are a concern, such as in medical equipment or in high-precision machinery.

Greater efficiency: Crown gears are more efficient than other types of gears, which means that they can transmit more power with less energy loss. This makes them a good choice for applications where efficiency is important, such as in electric motors or in industrial machinery.

Increased load capacity: Crown gears can support higher loads than other types of gears, which makes them a good choice for applications where heavy loads are present, such as in mining or construction equipment.

Reduced maintenance requirements: Crown gears are less prone to wear and tear than other types of gears, which means that they require less maintenance. This makes them a good choice for applications where maintenance is difficult or expensive, such as in remote locations or in harsh environments.

Uses Of Crown Gear

Differentials: Crown gears are used in differentials to transmit power from the driveshaft to the axle shafts. The crown gear is typically meshed with a pinion gear, which allows the power to be transferred at a 90-degree angle.

Steering gears: Crown gears are also used in steering gears to transmit power from the steering wheel to the steering linkage. The crown gear is typically meshed with a worm gear, which allows the power to be transferred at a 90-degree angle.

Lift trucks: Crown gears are used in lift trucks to transmit power from the engine to the lifting mechanism. The crown gear is typically meshed with a spur gear, which allows the power to be transferred at a 90-degree angle.

Conveyors: Crown gears are used in conveyors to transmit power from the driveshaft to the conveyor belt. The crown gear is typically meshed with a spur gear, which allows the power to be transferred at a 90-degree angle.

Robotics: Crown gears are used in robotics to transmit power from the actuators to the robot's joints. The crown gear is typically meshed with a spur gear, which allows the power to be transferred at a 90-degree angle.

Maintenance tips for Crown Gear

Inspect the gears regularly: Inspect the gears regularly for signs of wear and tear. Look for cracks, chips, or missing teeth. If you see any damage, replace the gear as soon as possible.

Lubricate the gears regularly: Crown gears should be lubricated regularly to prevent wear and tear. The type of lubricant you use will depend on the application. In general, you should use a lubricant that is compatible with the materials the gears are made of.

Keep the gears clean: Keep the gears clean to prevent dirt and debris from building up. This can cause the gears to wear out prematurely. You can clean the gears with a mild solvent or soap and water.

Avoid overloading the gears: Overloading the gears can cause them to wear out prematurely. Make sure that the gears are not being overloaded by the application.

Replace the gears as needed: If the gears are worn out, replace them as soon as possible. Worn-out gears can cause noise, vibration, and loss of efficiency.

We are one of the best crown gear manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!